Tag: SLR

-

Canon A-1 Mode Switch Repair

My Canon A-1 (which I fixed the wheeze on here but please don’t use that method because it’s a bad hack that could cause more harm than good) was doing something weird. Every so often, when taking a photo indoors in aperture priority mode (Av), I would notice that the camera’s settings would jump to…

-

Nikon FG Early Activation Hack

While I was working on the light meter for the Nikon FG, I thought of a ‘fix’ that I’d read about for another issue – making the light meter active as soon as the film door is closed. The FG, by default, will only activate its light meter after the film counter is on 1.…

-

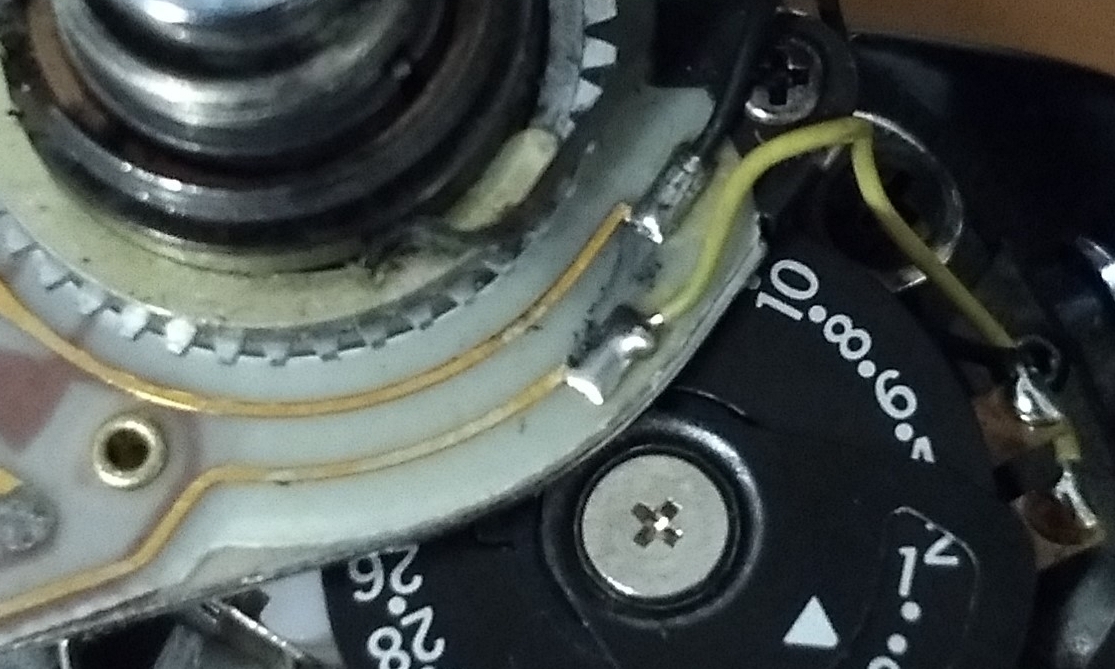

Nikon FG Light Meter Alignment

When I acquired an old family friend’s photographic enlargers a couple of years ago, they threw in a bag of other gear. In the bag was a Nikon F4 (still haven’t got it working – one day!) and a couple of lenses: a Series E 100mm and a Nikkor-H 85mm f/1.8. Too much fine glass…

-

Minolta X-9 Capacitor Replacement

Last year I bought three enlargers from a family friend, who also threw in a bag of other camera stuff. This included a Nikon F4 and a Minolta X-9, neither of which worked properly. The F4 is my dream fix, but it’s a complicated beast. The X-9 (also called/very similar to the X-300S or X-370N)…

-

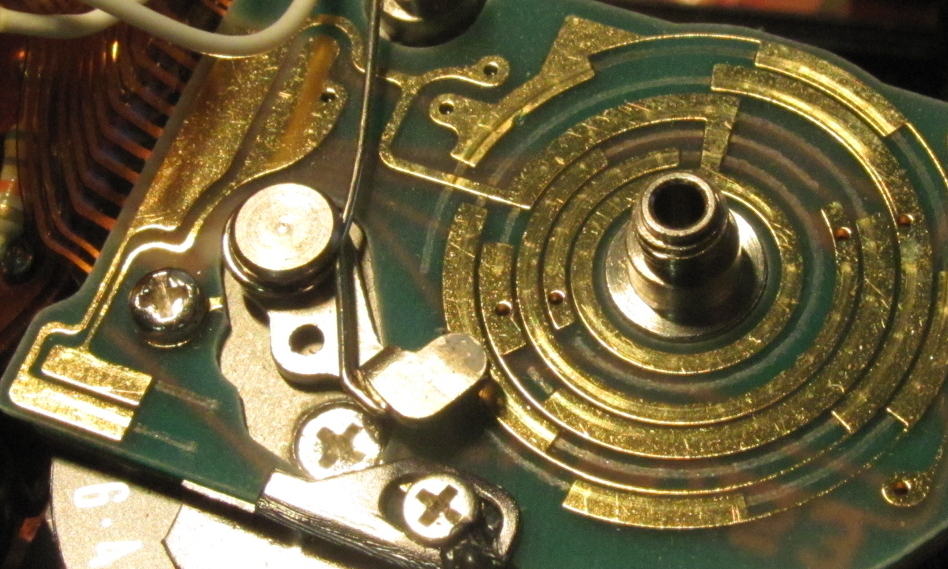

Minolta XE-5 Film Advance Repair

A couple of months ago, just before the birth of my son, I fixed the film advance on my Minolta XE-5. The lever had not been completing its action properly, and when it got to the end of its rotation there would still be some film winding left to do, so it would just return…

-

Canon FT QL mirror damper replacement

I thought I’d make my first post about some work done on my favourite camera: my dad’s old Canon FT QL. This fully mechanical SLR was built from 1966-72. It has through-the-lens metering (the only electrical function) and a nifty Quick Load system for film insertion (honestly not sure why it’s not ubiquitous in later…